Profiles tailored to your needs

From concept to finished profile

We are with you every step of the way when you want to create a new profile – from the first sketch to the finished product.

01

Tool design

We develop production tools and help you design the profile. We have our own design department and professional software.

02

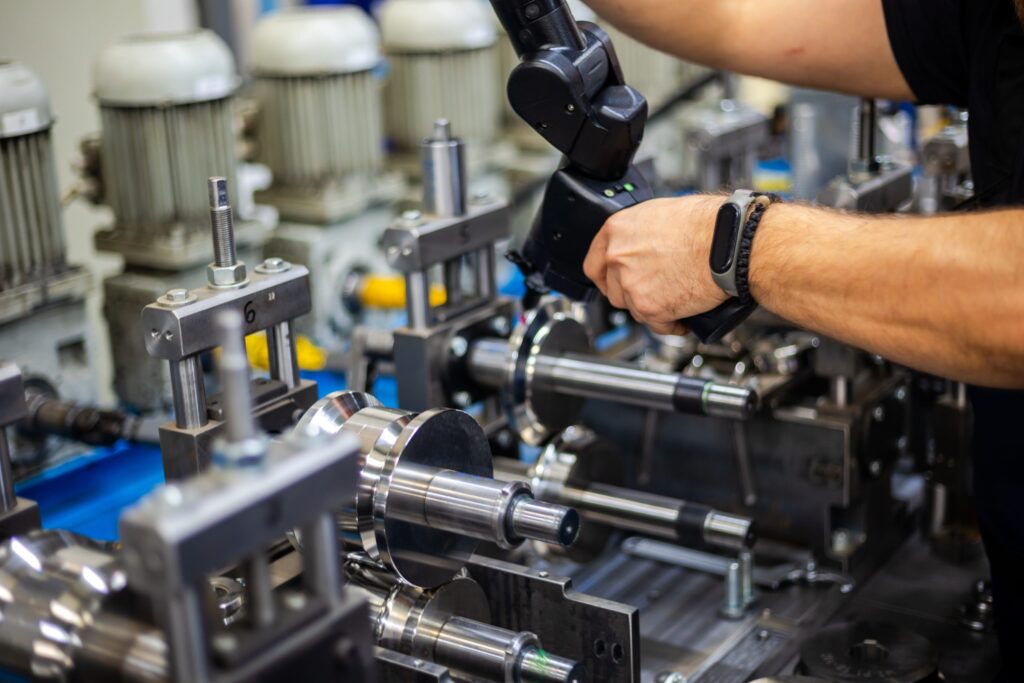

Tool production

We make tools at our own tool shop, using modern machinery.

03

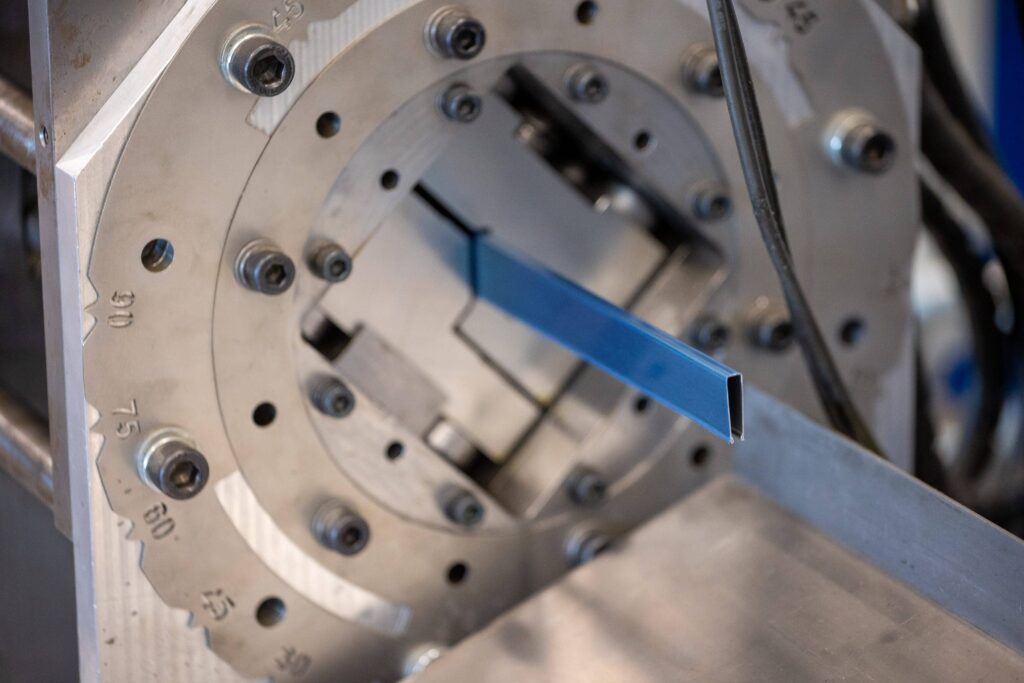

Production launch

We make the profiles on our own production lines, ensuring full control of the process.

04

Long-term partnership

After developing the profile, we ensure regular deliveries, flexible ordering options, and long-term production partnership.

Additional processes

more than production

Treatment and finishing

Holes, profile end coving, deburring, application of adhesive tapes, adhesive layers, and protective films.

Picking and packing

Cutting to size and packing individual pieces or sets according to the requirements.

Quality control

Verification according to the standards and tests adapted to the client’s requirements.

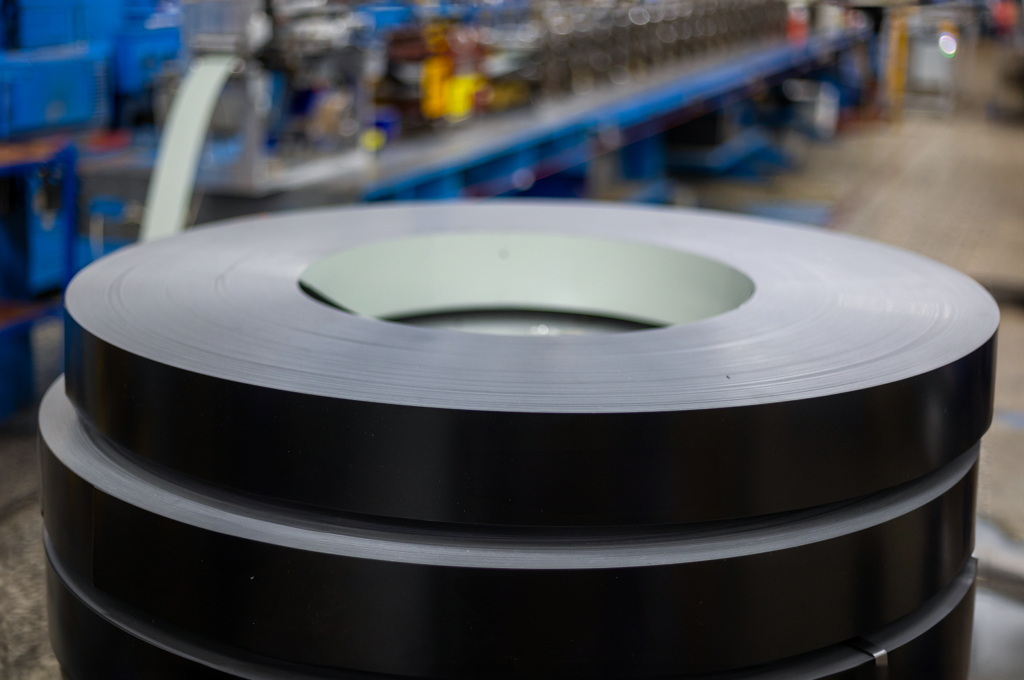

Materials

We specialise in the manufacture of profiles from finished painted sheets and stainless steel with a thickness of 0.15 mm or more. We also work with black steel, galvanised steel, aluminium, and other materials – it all depends on your needs.

Let’s talk about your project

Do you have an idea for a profile but do not know where to begin?

Perhaps you are trying to find the best solution? Write to us – we will help you choose the right process, design the tools, and handle production operations.

No strings attached, let’s just talk.